FEATURES AND BENEFITS

- Single-side high speed assembly

- High precision and high quality assembly.

- It increases productivity: there are no interruptions and up to 60 rivets per minute can be placed.

- Diversity. It is available in a wide range of materials: aluminium, steel and stainless steel.

- It does not deform surfaces after the riveting process is finished (painted, glazed…etc.).

- Different materials, with different types of manufacturing can be fastened: composites, laminates, heat treated materials, etc.

- Conical end to facilitate the hole entry

- It expands radially during installation to ensure the best hole fill.

- Having no mandrel means avoiding noises or short circuits resulting from residual portions of mandrels inside the body.

- They do not come loose from dynamic stress (vibrations in general).

- Their bulging or pre-shaped end provide a high torque value in the joint and a good resistance to shear strength.

MATERIALS TO BE FASTENED

Metal to plastic

Metal to wood

Metal to fiberglass

Metal to soft materials and low resistance materials in general.

Plastic to plastic

Plastic to soft materials and low resistance materials in general

APPLICATIONS

- Plastic industry

- Wood industry

- Automotive industry

- Electronics and electrical engineering

- Electrical appliances

- Injection moulded components

- Plastic in general

- Light fabrication in general

|

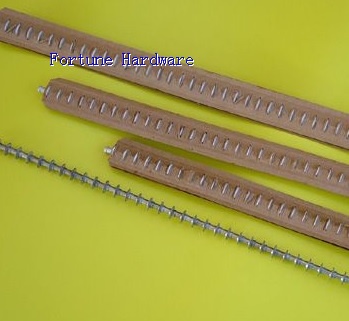

Screw

Screw

Plastic Fasteners

Plastic Fasteners