Products Category

Contact Us

E-mail: sales1@fortunehardware86.com

E-mail: sales2@fortunehardware86.com

Add: A2501,Oriental Times Plaza, North Huaqiang Rd, Futian District,Shenzhen,China

|

Product name : Stainless Steel Weld Nuts

Item : MTNUTWENST

material : Stainless Steel

|

| Details: |

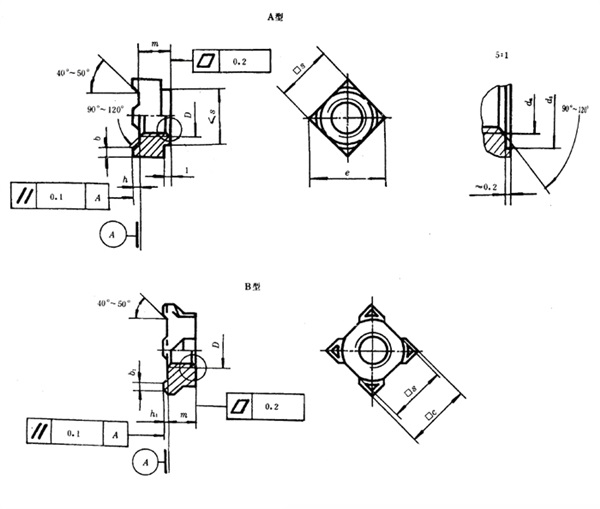

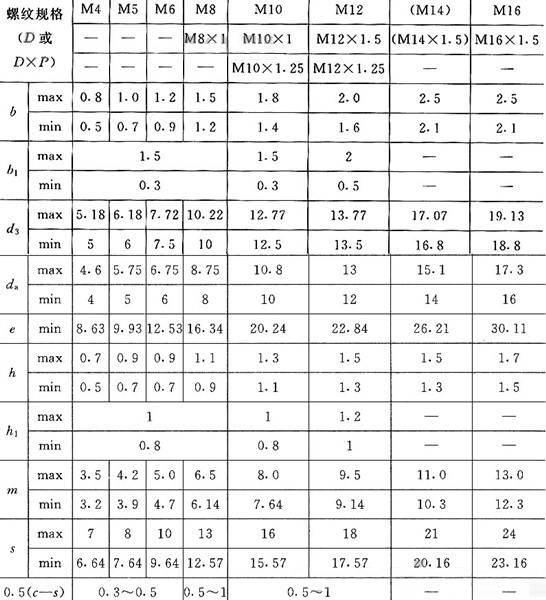

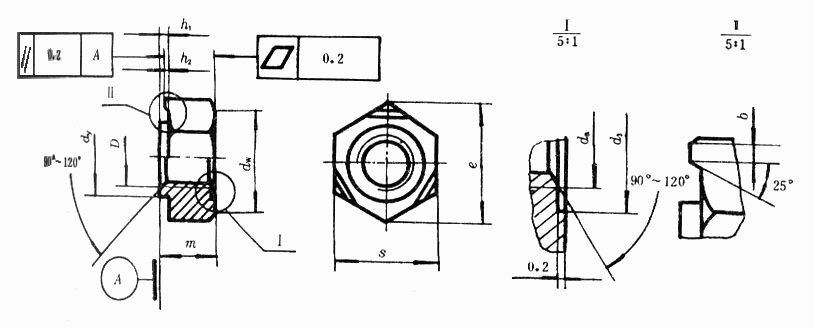

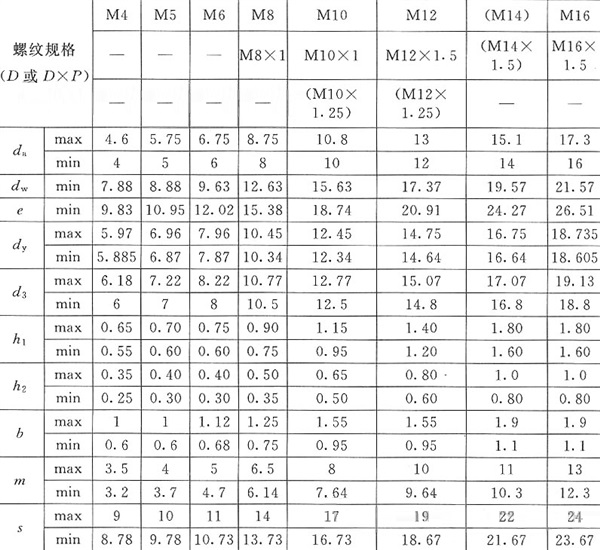

Standard: DIN928(Square),DIN929(Hex),DIN 977(Hex Flange), JIS B 1196-1994

Material: SUS301,304,18/8,0Cr18Ni9,X5CrNi1810,X10Cr13,410S21,if you need to use other stainless steel, please let us know. Heat Treatment: None for normal, If you have special hardness requirement, please let us know.

Surface Hardness:220HV is Normal, 750HV max after Quench with SUS410

Finish:None.

Head:N/A

Tensile strength:700N/mm2

Thread Direction:Normal is right hand/dextrorotation, if you want left hand, please let us know. Refer to document as below:  Stainless Steel Weld Nuts.pdf Stainless Steel Weld Nuts, when creating a sculpture or other product out of metal, a welder will occasionally need to attach a weld nut. Weld nuts function in the same way as standard hardware nuts, providing a threaded cylinder to accommodate a bolt. The difference is that welded nuts are meant to be fastened to a welded project and therefore often have additional surface area to attach them to an object.

"Stainless Steel" - With the addition of 12% chromium to iron, stainless steel is formed. The chromium protects the iron against most corrosion or red colored rust; thus the term "stainless steel". The ability of stainless to form a thin layer of protection on its outside surface, called a "passive film", is its most important characteristic in preventing corrosion.

"18-8" - 300 series stainless steel having approximately (not exactly) 18% chromium and 8% nickel. The term "18-8" is used interchangeably to characterize fasteners made of 302,302HQ,303,304,384, XM7, and other variables of these grades with close chemical compositions. There is little overall difference in corrosion resistance among the 18-8 types, but slight differences in chemical composition do make certain grades more resistant than others against particular chemicals or atmospheres.

Austentic - Refers to 300 series stainless, the most popular of the stainless alloys accounting for 85%-90% of stainless fasteners sold Named for sir Robert Williams Austen, an English metallurgist, austentic stainless is a crystal structure formed by heating steel, chromium, and nickel to a high temperature where it forms the characteristics of 300 series stainless steel.

And below is the common drawing for this kind:    |

| Related Products : |

Screw

Screw

Plastic Fasteners

Plastic Fasteners