E-mail: sales1@fortunehardware86.com

E-mail: sales2@fortunehardware86.com

Add: A2501,Oriental Times Plaza, North Huaqiang Rd, Futian District,Shenzhen,China

|

Product name : Stainless Steel Serrated Lock Washers

Item : MTWSHLKWST

material : Stainless Steel

|

| Details: | ||||||||||||||||||||||||||||||||||||||||||||

Standard: DIN6797/DIN6798, GB/T862.1-1987,GB/T862.2-1987,GB/T861.1-1987,GB/T861.2-1987

Material: SUS301,304,18/8,0Cr18Ni9,X5CrNi1810,X10Cr13,410S21,if you need to use other stainless steel, please let us know.

Heat Treatment: None for normal, If you have special hardness requirement, please let us know.

Surface Hardness:220HV is Normal, 750HV max after Quench with SUS410

Finish:None.

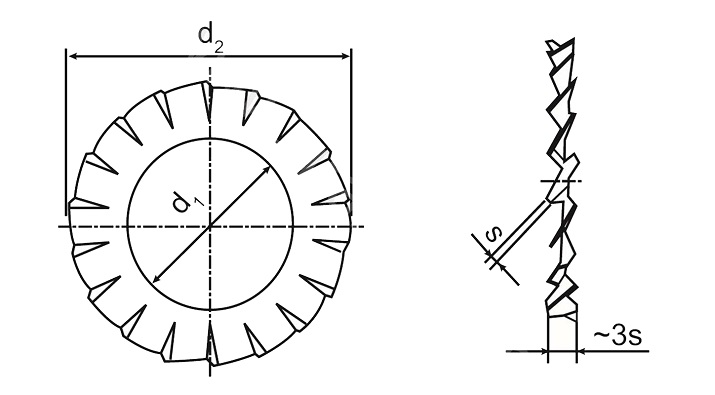

Stainless Steel Serrated Lock Washers is a toothed lock washer, also known as a serrated washer or star washer, has serrations that extend radially inward and/or outward to bite into the bearing surface. This type of washer is especially effective as a lock washer when used with a soft substrate, such as aluminium or plastic, but can still resist rotation more than a plain washer on hard surfaces, as the tension between washer and the surface is applied over a much smaller area (the teeth). There are four types: internal, external, combination, and countersunk. The internal style has the serrations along the inner edge of the washer, which makes them more aesthetically pleasing. The external style has the serrations around the outer edge, which provides better holding power, because of the greater circumference.The combination style has serrations about both edges, for maximum holding power. The countersunk style is designed to be used with flat-head screws.

Tooth lockwashers are also used for ground bonding where a metal lug or object must be electrically bonded to a surface. The teeth of the washer cut through surface oxides, paints or other finishes and provide a gas-tight conductive path. In these applications the washer is NOT placed under the head of the screw (or under the nut), it is placed between the surfaces to be bonded. In such applications the tooth washer does not provide any traditional/anti-rotation locking features. "Stainless Steel" - With the addition of 12% chromium to iron, stainless steel is formed. The chromium protects the iron against most corrosion or red colored rust; thus the term "stainless steel". The ability of stainless to form a thin layer of protection on its outside surface, called a "passive film", is its most important characteristic in preventing corrosion.

"18-8" - 300 series stainless steel having approximately (not exactly) 18% chromium and 8% nickel. The term "18-8" is used interchangeably to characterize fasteners made of 302,302HQ,303,304,384, XM7, and other variables of these grades with close chemical compositions. There is little overall difference in corrosion resistance among the 18-8 types, but slight differences in chemical composition do make certain grades more resistant than others against particular chemicals or atmospheres.

Austentic - Refers to 300 series stainless, the most popular of the stainless alloys accounting for 85%-90% of stainless fasteners sold Named for sir Robert Williams Austen, an English metallurgist, austentic stainless is a crystal structure formed by heating steel, chromium, and nickel to a high temperature where it forms the characteristics of 300 series stainless steel.

And below is the common drawing for this kind: Below chart show some typical dimensions of them, you can refer it, or can you change it for your own design, if you want know more standard dimensions of screw , you can contact us.

|

| Related Products : |

|

Screw

Screw

Plastic Fasteners

Plastic Fasteners