Products Category

Contact Us

E-mail: sales1@fortunehardware86.com

E-mail: sales2@fortunehardware86.com

Add: A2501,Oriental Times Plaza, North Huaqiang Rd, Futian District,Shenzhen,China

|

Product name : Stainless Steel Pan Head Self Drilling Screw

Item : MTSCRPADST

material : Stainless Steel

|

| Details: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

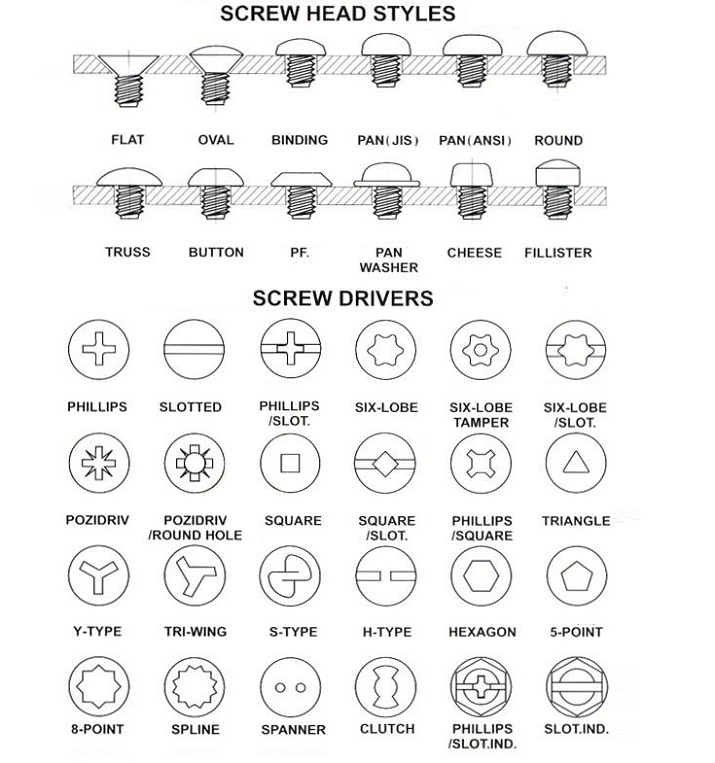

Standard: DIN7504 (Any kind of screw Driver, you can choose it from our following picture), ISO 15481, GB/T 15856.1-2002

Material: SUS301,304,18/8,0Cr18Ni9,X5CrNi1810,X10Cr13,410S21,if you need to use other stainless steel, please let us know.

Heat Treatment: None for normal, If you have special hardness requirement, please let us know.

Surface Hardness:220HV is Normal, 750HV max after Quench with SUS410

Finish:None.

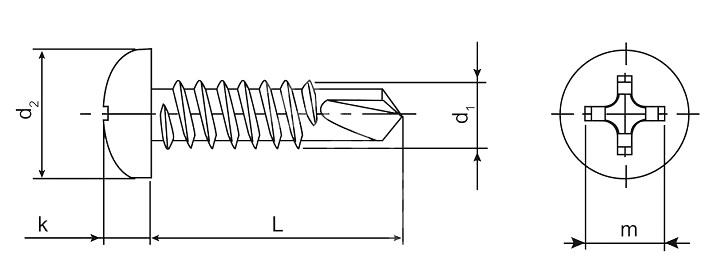

Head:Pan

Tensile strength:700N/mm2

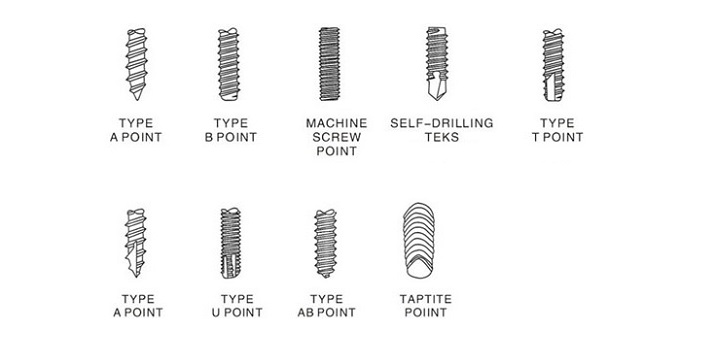

Thread Direction:Normal is right hand/dextrorotation, if you want left hand, please let us know. Refer to document as below:  Stainless Steel Pan Head Self Drilling Screw.pdf Stainless Steel Pan Head Self Drilling Screws belong to Self-Drilling Screws, also known as Tek screws, eradicate the need for a pre-drilled hole and allow drilling and tie to be done in the same motion. Self-drilling screws are used to create a hole and form their own mating thread in the process.

"Stainless Steel" - With the addition of 12% chromium to iron, stainless steel is formed. The chromium protects the iron against most corrosion or red colored rust; thus the term "stainless steel". The ability of stainless to form a thin layer of protection on its outside surface, called a "passive film", is its most important characteristic in preventing corrosion.

"18-8" - 300 series stainless steel having approximately (not exactly) 18% chromium and 8% nickel. The term "18-8" is used interchangeably to characterize fasteners made of 302,302HQ,303,304,384, XM7, and other variables of these grades with close chemical compositions. There is little overall difference in corrosion resistance among the 18-8 types, but slight differences in chemical composition do make certain grades more resistant than others against particular chemicals or atmospheres.

Austentic - Refers to 300 series stainless, the most popular of the stainless alloys accounting for 85%-90% of stainless fasteners sold Named for sir Robert Williams Austen, an English metallurgist, austentic stainless is a crystal structure formed by heating steel, chromium, and nickel to a high temperature where it forms the characteristics of 300 series stainless steel.

Pan head screws are a type of fastener that binds materials together or tightens the connection of two or more materials. The top of a pan head screw is wider than any other screw head. This characteristic makes the screw resemble a frying pan. Pan head screws feature a helical ridge known as a thread that is wrapped around a cylinder. This allows the screw to easily descend into the material it is fastening. Other types of screw heads include button, round, truss, flat and oval. These types are all more abbreviated and require more precise screwdriver work. To fasten a pan head screw, rest a screwdriver's end in the groove on top of the head and turn it clockwise. This will fasten the materials that are being joined or tightened.

You can refer to below chart/list of Screw head/Thread ending

Thread ending:  And below is the common drawing for this kind:  Below chart show some typical dimensions of them, you can refer it, or can you change it for your own design, if you want know more standard dimensions of screw , you can contact us.

|

| Related Products : |

Bolt

Bolt Plastic Fasteners

Plastic Fasteners